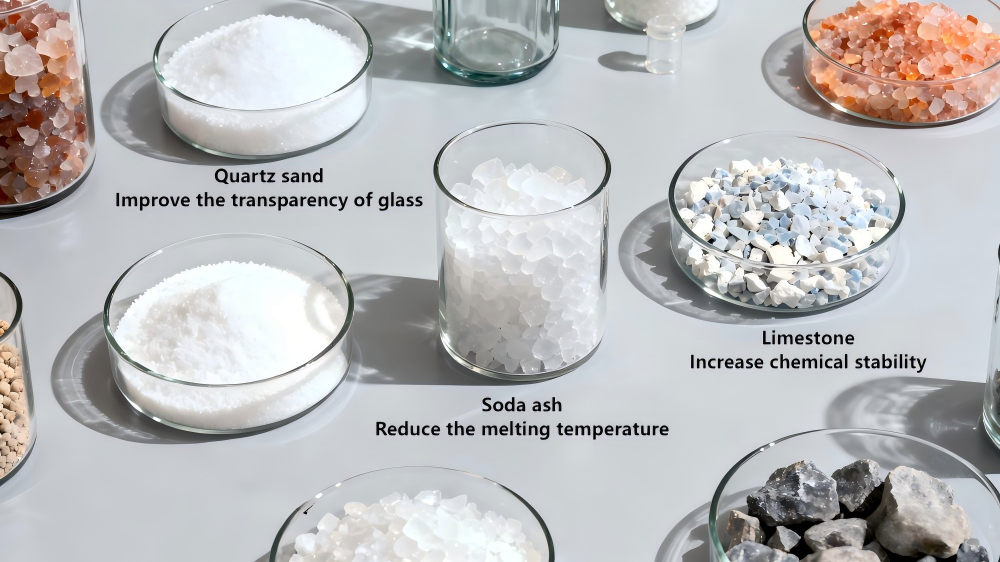

The main raw materials of glass bottles are quartz sand, soda ash and limestone. However, different manufacturers will adjust the proportion of raw materials according to the product characteristics and market demand. For instance, when manufacturing glass bottles for high-end cosmetics, some manufacturers will choose quartz sand of higher purity to ensure the transparency and smoothness of the glass bottles. When manufacturing ordinary beverage bottles, some manufacturers may appropriately lower the purity requirements for raw materials to control costs.

The differences are even more obvious in the raw material pretreatment stage. Some manufacturers with advanced technology will use fine crushing equipment to break down raw materials into extremely uniform particles, ensuring that the raw materials can fully react during the subsequent melting process. At the same time, they will also apply efficient drying technology to thoroughly remove the moisture from the raw materials and prevent the formation of bubbles during melting. In addition, these manufacturers will be equipped with professional iron removal devices to precisely remove iron impurities from raw materials and prevent glass bottles from having defects such as color spots.

In contrast, some small-scale manufacturers may, due to limitations in funds and technology, use relatively simple crushing equipment, resulting in poor uniformity of raw material particles. The drying process may only use natural sun-drying, resulting in incomplete drying. The iron removal equipment is also relatively simple and the iron removal effect is not good. All these may lead to unstable quality of the produced glass bottles.